In the thousand-year heritage of Yixing teapot making, clay selection is the foundation, shaping is the skeleton, but firing is what gives the teapot its soul. Whether a teapot can develop a warm texture, maintain its unique “breathable but watertight” quality, or even become a collectible masterpiece, all depends on how it is fired.

Today, we will explore the traditional Yixing teapot firing process, step by step — unveiling the conversation between clay and fire, and showing how a raw clay body transforms into a teapot of life and spirit.

1. Preparation Before Firing: The Final Check of Clay Bodies

Firing doesn’t mean directly sending a dried clay teapot into the kiln. Careful pre-treatment is essential.

-

Inspection: Artisans use strong light to check for cracks, bubbles, or hidden flaws. Any issue must be repaired with slip (liquid clay), otherwise the piece is discarded. “Better none than flawed” is a rule every Yixing craftsman follows.

-

Loading the kiln: In traditional wood-firing, teapots are placed inside saggers (protective clay containers). Placement is critical — thin-walled teapots are set in stable zones, while different clay types are separated because each reacts differently to heat.

👉 If you want to try making your own clay teapot, check out our Yixing teapot making tools.

2. The Temperature Code: Firing Secrets of Different Clays

The essence of Yixing firing lies in precise temperature control — even a 10°C difference can change the teapot’s texture and color.

-

Purple clay (Zini): Best fired at 1180–1220°C. Too low and the body is porous and rough; too high and it vitrifies, losing breathability.

-

Red clay (Hongni): Requires 1100–1150°C. Extremely sensitive; even slight overheating may collapse the body.

-

Green clay (Lüni): Best at 1150–1180°C, producing a smooth, jade-like green hue.

Equally important is heating and cooling speed. Traditionally, wood kilns heat slowly for 8 hours to 600°C, then gradually rise to the target range. After firing, cooling takes three days naturally — rapid cooling risks invisible cracks.

3. The Magic Moment: Formation of the Dual Pore Structure

One of the most fascinating qualities of Yixing teapots is that they are breathable but watertight. This is created during firing:

-

Around 800°C, quartz expands and clay minerals begin melting.

-

At 1000°C, mica decomposes, releasing gases that form microscopic pores.

-

At full temperature, these pores connect into a dual-pore structure:

-

Closed pores trap water, preventing leaks.

-

Connected pores allow airflow, helping tea aroma to linger.

-

This is why high-fired purple clay suits Pu-erh and black tea, while medium-fired red clay works better with green or white teas.

4. Kiln Types and Their Unique Fire Marks

Different kilns give Yixing teapots different finishes:

-

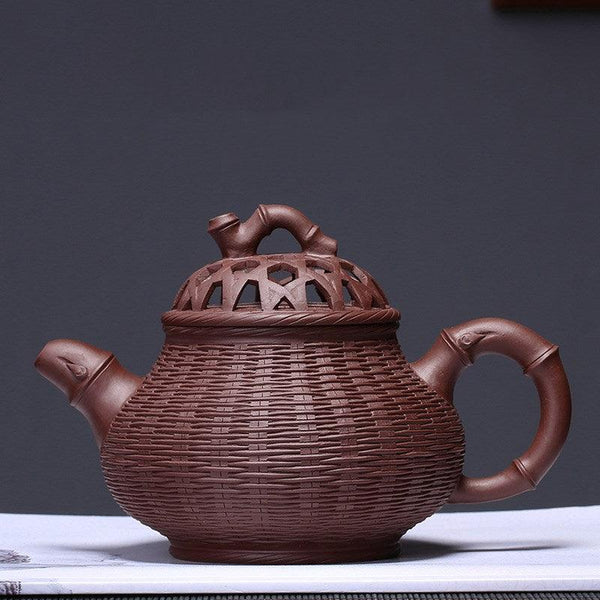

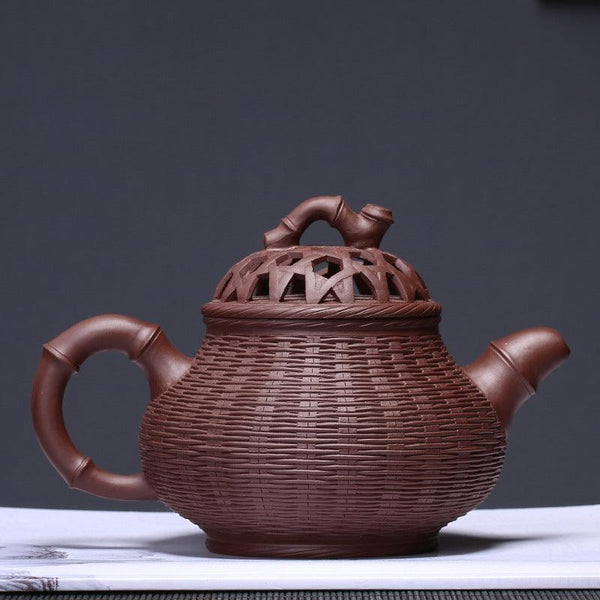

Wood kiln: Fueled by pine wood. Ash falls on teapots, creating unique “kiln-change” patterns — golden spots, dark textures, or natural ash glaze. Each teapot is one-of-a-kind. However, yield is low (~60%).

-

Electric kiln: The most common today. Temperature is controlled within ±1°C, ensuring stable quality and high success rates (90%+). Many everyday-use Yixing teapots are fired this way.

-

Gas kiln: Faster than wood, slower than electric. Produces a soft fire sheen on the surface, balancing tradition and efficiency.

5. The Final Test: Standards of a Successfully Fired Teapot

When the kiln cools and is opened, each teapot undergoes strict inspection:

-

Shape: Does the lid fit tightly? Is the body symmetrical?

-

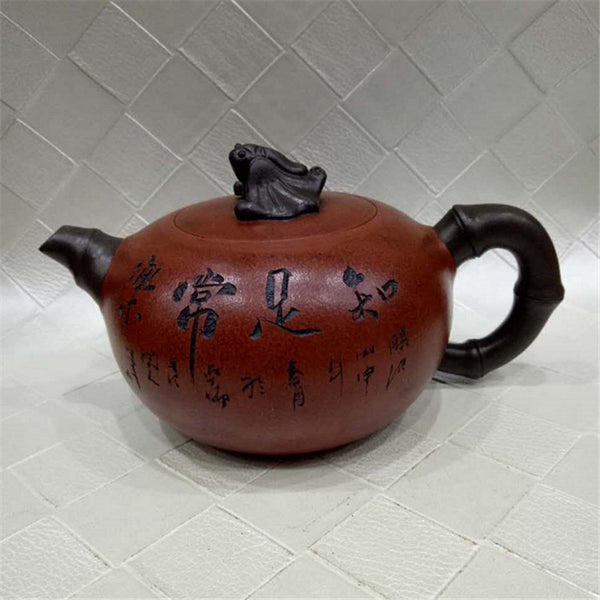

Color: Does the clay show its expected tone? (e.g., deep liver-purple for Zini, bright red for Hongni).

-

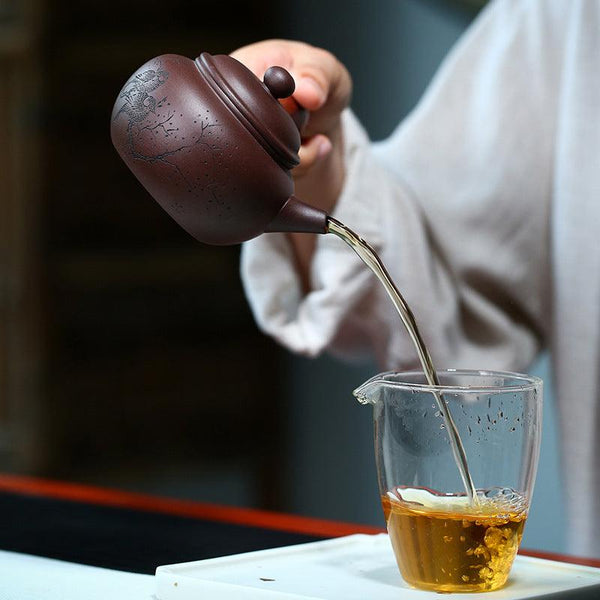

Quality: A clear sound when tapped means proper firing. When rinsed with hot water, the teapot should breathe evenly without leaks.

Only those that pass every test are kept for engraving or finishing. Inferior pieces are destroyed or repurposed — never sold.

Conclusion: Firing as the Teapot’s “Second Life”

From clay body to finished teapot, firing is not just the effect of fire, but the wisdom of artisans — their mastery of clay, temperature, and patience.

Each Yixing teapot is a collaboration of earth and fire, guided by human hands. When you select a teapot at yixingteaart.shop, look closely at its firing style:

-

Wood-fired pieces carry unique fire marks,

-

Electric kilns ensure reliable daily use,

-

Gas kilns balance individuality and refinement.

When you brew tea with a Yixing teapot, you are holding not just a vessel — but the second life of clay, reborn through fire and craftsmanship.