Nowadays, drinking tea has become a new fashion, people will choose to buy a better tea set to drink tea. In the many tea sets, the purple sand pot (Zisha pot) is one that can not be ignored. Many are familiar with the name and reputation of Yixing teapots, known for their aromatic and durable qualities. However, the process of crafting these teapots might be a mystery to many. So, how is a Zisha pot made? This article aims to provide a detailed insight into their crafting process.

What are the advantages of purple sand pots?

Since the Ming Dynasty, Zisha pots have developed over 500 years, with a variety of different and unique categories. Although everyone knows about purple clay pots, not everyone may understand the advantages of purple clay pots. In fact, purple sand pot is quite popular because it has these advantages:

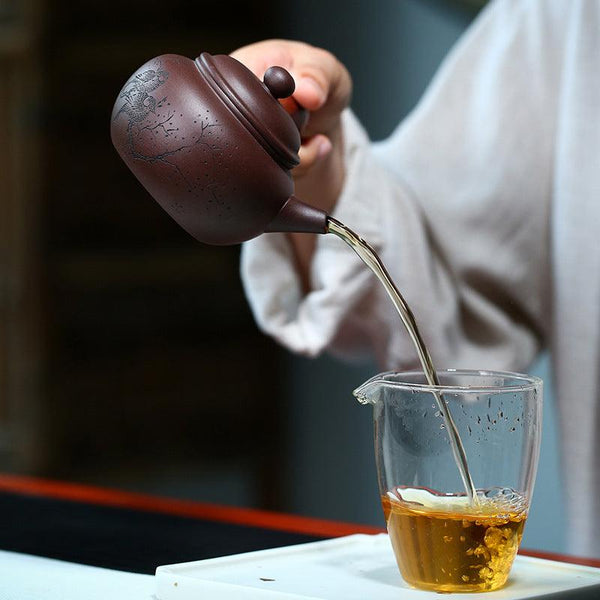

- Retains Tea Fragrance: Especially after prolonged use, Yixing teapots retain the aroma of brewed tea.

- Excellent Breathability: With a dual-pore structure, Yixing teapots effectively prevent tea leaves from going stale.

- Easy to Clean: Simply rinsing with water is sufficient, eliminating any lingering odors.

- Absorbs Tea Essence: Even when empty, pouring boiling water into a Yixing teapot brings out the fragrance of tea.

- Antibacterial Properties: Yixing teapots, durable and porous, can absorb tea residues and possess antibacterial properties.

- Fat Decomposition: Natural iron content in Yixing teapots aids in breaking down fats, making them suitable for weight-conscious individuals.

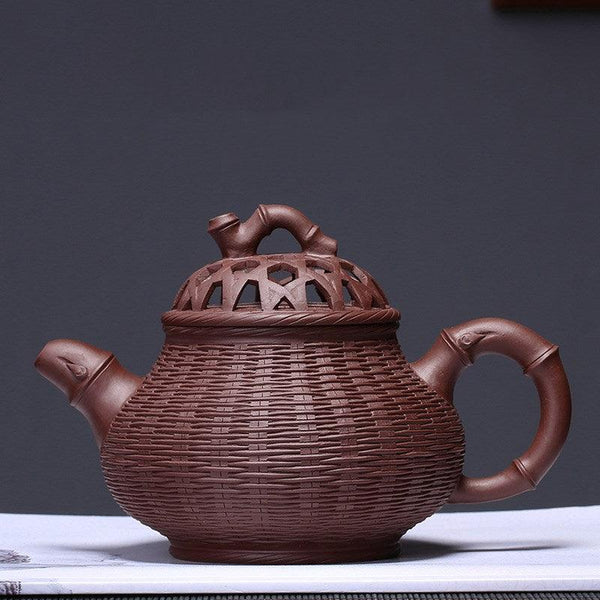

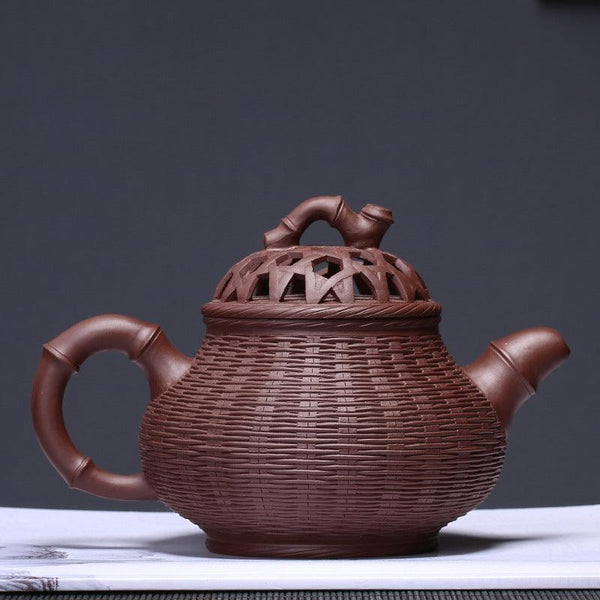

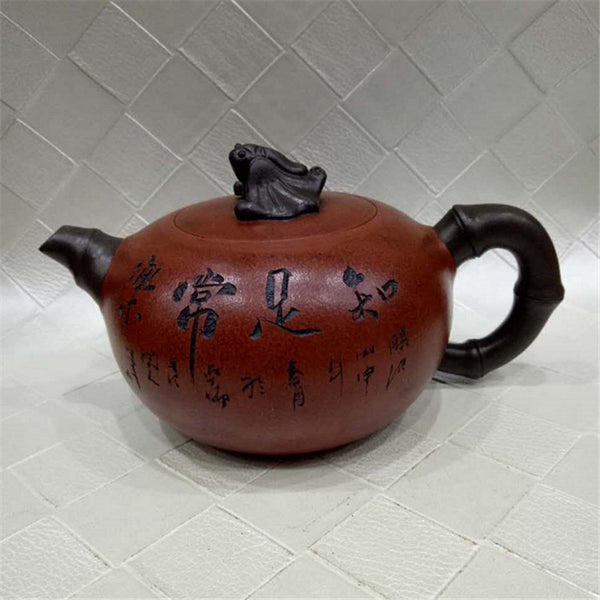

- Aesthetic Appeal: Yixing teapots boast unique colors and designs, adding to their allure.

- Superior Performance: Even when filled with boiling water in winter, Yixing teapots do not crack, and their slow heat conduction prevents scalding during tea brewing.

- Durability: Frequently depicted in television dramas, Yixing teapots are cherished for their longevity and become smoother and more adorable with prolonged use.

What is the process of making Zisha pots?

The raw materials for Zisha pots, which are mainly produced in Yixing, Jiangsu Province, are clay, paper and white clay. From ancient times to the present, people have held Zisha pots in high esteem. Many people are also particularly curious about the making of Zisha pots. In general, making a Zisha pot requires going through these steps:

(1) Preparation of raw materials:

To make a Zisha pot, you need to prepare raw materials such as paper, Zisha clay, water, bamboo scorn, and white clay. When choosing Zisha clay, look for one that is fine in texture and not prone to cracking. The quality of zisha clay is especially important as it is the core raw material for zisha pots, providing heat preservation, fire resistance, and abrasion resistance. The white clay used to make the tire membrane also needs to meet the basic requirements;

(2) Preparing tools:

Tools are naturally needed to make a good Zisha pot, and commonly used tools include the rectangular car, the bright needle, the clapper, the sharp knife, the hitch, and the clay stool;

(3) Processing raw materials:

After preparing the raw materials, it is necessary to remove the impurities in the raw materials to ensure their purity. After the raw materials are screened, water needs to be added to grind the raw materials until they become mud;

(4) Hand-beating:

In the production process of Zisha pots, hand-beating is a very important part. The so-called hand beating is to knead the soft clay blanks and remove the air from them. Then, the processed clay blank is pinched into a rough billet, and then flattened, and repeated pinching, squeezing, pulling, and pinching are used to make it into the right shape. It is important to note that you must have a rough idea of what you want the teapot to look like before you make it, and it is even better if you can draw it;

(5) Carving:

When the Zisha pot has a basic shape and look, we can design some patterns and designs to be carved on the teapot. This step is very need patience, usually use paste and hollowing and other techniques;

(6) Firing:

At this step, the teapot has been molded and has patterns and motifs, the next step is firing. Of course, before firing, the pots need to be dried to ensure that they are sufficiently dry. This is done to prevent the zisha pot from bursting during firing. The firing of the zisha pots is done in a high temperature ceramic firing method, and the temperature needs to reach between 1000℃ and 1200℃;

(7) Polishing:

The finished fired zisha pots may have some imperfections. In order to ensure the beauty of zisha pots, we need to retouch and polish it. Generally, after finishing and polishing, the Zisha pot is very smooth and delicate;

(8) Glaze:

If you want to protect the zisha pot, you need to glaze it after finishing. At present, the glaze is mainly used inorganic glaze. Specific operation process, is a high temperature baking, so that the glaze can be thoroughly integrated with the purple sand pot;

(9) Huan color:

At this point, the zisha pot has been considered a finished product. Of course, we can also make it more unique, such as coloring it. With a unique color, the appearance of the pot will be a little better;

(10) Inspection and Packaging:

The output of zisha pots needs to go through strict quality inspection. After making sure that the zisha pot meets the required standards, it can be packaged.

The above is the production process of zisha pots related knowledge, we must have understood. The production of zisha pots is very delicate, each link needs to be doubly attentive.